|

4.2.1

|

Adapt bobbin size

|

PND500

|

|

4.2.2

|

Cage max rotation speed

|

704.1r/min

|

|

4.2.3

|

Adapt bobbin width

|

375mm

|

|

4.2.4

|

Bobbin clamping form

|

Pneumatic tightening

|

|

4.2.5

|

Tension form

|

Mechanical friction

|

|

4.2.6

|

Bearing mode

|

Large bearing support

|

|

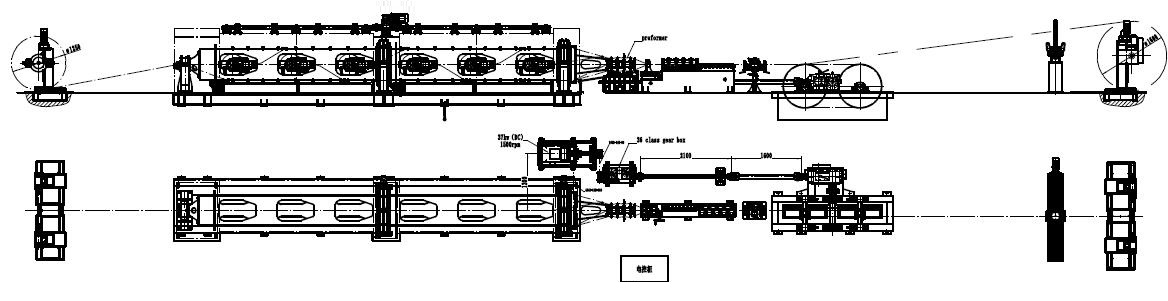

4.2.7

|

End-shaft type of pay-off frame, frame

body adopts high-quality plate numerical control cutting, integral bending

process, few welding positions, clean appearance, high mechanical strength

after high temperature annealing, and final integral boring processing, high

precision and stable operation

|

|

4.2.8

|

The spool holder is pneumatically clamped

and released, and has a pneumatic mechanical lock protection device. When the

spool holder is supplied with air, the lock protection of the spool can be

opened and the spool thimble device can be opened in sequence; After that,

the tightening of the spool is completed in turn and the pneumatic locking

protection device enters the locked state. The entire operation process is

fast, efficient, safe and convenient. The cradle base adds a wire reel

bracket

|

|

4.2.9

|

The pay-off in the spool frame uses

mechanical friction to provide tension, and the tension is manually adjusted

|

|

4.2.10

|

The cradle is equipped with a

"movable balance" device, which can effectively avoid uneven

rewinding wires and prevent the phenomenon of heavy weight

|

|

4.2.11

|

At the exit of the pay-off end in each

pay-off frame, a set of tic-tac-toe wire rollers is added, and a set of wire

rollers is also added to the outside of the outlet shaft head, which is

directly extended to the outer guide wheel group of the cylinder, effectively

avoiding the core Scratch

|

|

4.2.12

|

The body rear end, middle and outlet end of the cylinder adopt

bearing support. The large bearings in the middle and outlet end adopt

new-style oil-air lubrication and labyrinth seal, which have good lubrication

effect, short oil return distance, fast cooling speed, multiple functions,

all The function is integrated into each bearing support separately, no need

to set up a separate oil tank, the appearance is clean and easy to maintain

|

|

4.2.13

|

The large bearings at the middle and

outlet ends have high-temperature overload shutdown protection and lubricant

over-temperature alarm functions. After the alarm, the whole machine will

automatically stop and brake, and display the alarm prompt on the man-machine

interface

|

|

4.2.14

|

The cylindrical thick-walled steel pipe is

made by the CNC intersecting wire cutting machine as a whole, then the

large-scale annealing furnace is annealed to enhance the mechanical

performance, and then the large-scale machine tool is integrally finished.

The 6-disc cylinder body lifting is tested by a dynamic balancing machine.

After the overall assembly is completed, the on-site automatic balancing

instrument will measure the vibration value and dynamic balance value during

operation to ensure the stability of operation

|

|

4.2.15

|

The main engine adopts butterfly,

multi-group, pneumatic and caliper brake device, which is sensitive and

reliable.

|

|

4.2.16

|

The host adopts the external wiring

method, lengthened and thickened cylinder, super large wire hole, equipped

with multiple well-type guide rollers and guide wheels, so that the wiring is

smoother, no bends, no scratches, and no skipping

|

|

4.2.17

|

The rear support seat of the main engine,

the middle and the large bearing seat of the outlet end are all made of gray

iron cast material with lost foam process, which is not shaped, fully absorbs

vibration, reduces noise, and has a beautiful appearance

|

|

4.2.18

|

The main engine adopts a new type of front

drive, the cylinder does not bear torque, and the cylinder is fully prevented

from cracking. Using large modulus toothed belt transmission, effectively

avoiding loss of rotation

|

|

4.2.19

|

The monofilament pre-deformation device is

composed of multiple sets of guide pulleys, including a positioning disk, two

fixed guide pulleys, and a sliding guide pulley. The distance of each group

of guide disks is adjusted according to the curvature of the wire core to

realize the modification. , The whole set of device is installed on the main

shaft extending from the twisting head, the structure is intuitive and easy

to adjust

|

|

4.2.20

|

The cylinder body is installed on the

integral welding base. The base is made with the help of a special platform,

and then is finished by the gantry planer. It is easy to install and has a

high level of level.

|

|

4.2.21

|

There is a touch-type broken wire parking

protection device, which can stop and brake the whole machine in time when

the wire is broken and the wire is finished.

|

|

4.2.22

|

The protective cover adopts a box-type

closed safety cover with a two-stage design. Each section can electrically

control the opening and closing of the protective cover. It has the function

of automatic parking when the cover is opened. The exterior is equipped with

an observation window; the interior of the protective cover is equipped with

working lights. , Soundproof cotton is laid in the shield to effectively

reduce noise

|

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.