|

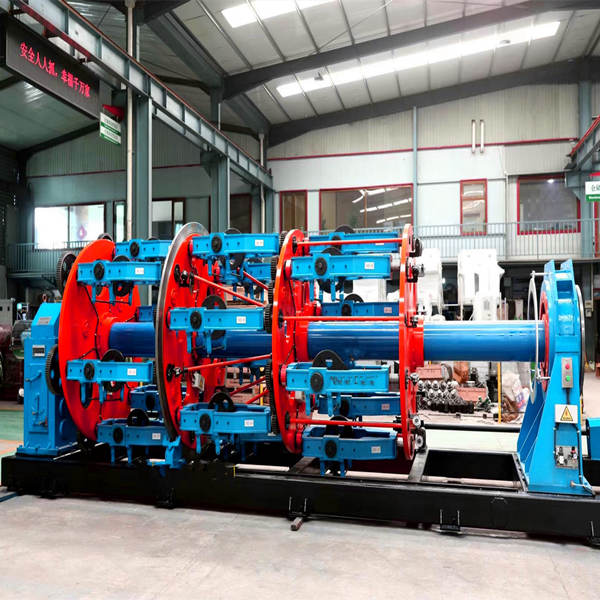

4.1.4Tension form and hysteresis tension

4.1.5 ﹣ loading mode ﹣ end shaft type, electric tightening

4.1.6 ﹣ disconnection

protection ﹣ touch type

4.1.7 ﹣ braking form ﹣ air pressure braking

4.1.8 Threading mode: External routing

4.1.9 ﹣ drive mode ﹣ independent motor drive

4.1.10 installation mode: "end shaft type

electric clamping, mechanical locking, back stop" is safe and stable,

and it is not easy to throw out. It is convenient to load and unload the

coil, and the coil is loaded into the cradle with the help of the crane in

the workshop.

4.1.11 production process of pay off frame:

"steel welding", with large bearing capacity, boring after overall

annealing, high precision and durability.

4.1.12 setting out tension: the

"hysteresis tension" is used to provide the tension required for

setting out. The tension is 1kg-8kg. The machine is shut down in the cradle

for adjustment. The manual operation surface is installed with digital

adjustment, which is convenient for micro adjustment and even tension output,

and is not easy to fail.

4.1.13 broken wire protection: double

protection functions of "ring touch type" and "bottom bar

touch type" broken wire parking are respectively added at the outlet end

of the main engine and under the side of the cylinder, which is convenient

for automatic parking after broken wire and finished wire.

4.1.14 ﹣ cylinder structure:

the cylinder adopts 3 + 3 two-stage, whole pipe bearing structure, double row

roller self-aligning bearing support is adopted in the support frame of pay

off inlet end, and a set of thrust bearing is added to ensure the bearing

capacity of axial movement of the cylinder; two groups of large bearing

support are adopted in the middle and outlet end, with flange butt joint,

which is convenient for maintenance and disassembly.

4.1.15 manufacturing process of cylinder: the

cylinder is made of thick wall steel pipe, the internal stress shall be

eliminated before processing, and the dynamic balance shall be corrected

after processing, and the opening deviation of each cylinder must be ≤ 2mm in the same axis and circumferential direction. The maintenance

and inspection holes for the electric slip ring are reserved between the

flange plates of the two holes of the cylinder, which is convenient for

maintenance and does not affect the bearing strength.

4.1.16 large bearing lubrication system

(patent): large bearing adopts new oil air lubrication; single oil pump motor

oil supply, thin oil lubrication, labyrinth seal, with dual functions of

lubrication and cooling, bearing seat cavity oil storage, no need to set a

single oil tank, small floor area, clean working condition.

4.1.17 supporting seat: the rear supporting

seat, middle bearing seat and outlet bearing seat of the main engine are gray

iron castings with EPC process, which can fully absorb vibration, reduce

noise and have beautiful appearance.

4.1.18 braking form: plane air compressor

braking device is adopted; unified coordination by PLC: variable frequency

motor controller, braking resistor, air compressor, etc. jointly complete the

slow stop, fast stop, emergency stop and other operations of the whole

machine. Ensure the synchronization of the whole machine.

4.1.19 base: "high strength, steel plate

welding" base, the base is made with the help of a special platform,

after high temperature annealing, and then one-time finishing by large gantry

milling machine, with high mechanical strength, convenient installation and

high concentricity.

4.1.20 threading mode: the main machine adopts

the "external wiring" mode, lengthening and thickening the

cylinder, 15mm core wire through hole, 10mm leather wire through hole, and

many alloy nozzles or guide wheels to make the wiring more smooth, without

bending, scratching and job hopping.

4.1.21 monitoring and protection: the main

engine is equipped with protection functions such as large bearing high

temperature monitoring, lubricating oil flow monitoring, etc., which can

automatically stop the machine in case of overrun operation, and prompt in

the man-machine interface, so as to avoid damaging other hardware in bad

state operation and get timely maintenance.

4.1.22 installation mode: the unit adopts

"surface installation" mode, without foot bolt or other bolt type

fixation, and adopts special damping pad iron for support and adjustment.

4.1.23 safety protective cover (patent): the

protective cover adopts electric up turning, sectional opening and fully

closed structure, with built-in sound-absorbing board partition layer, fully

absorbing noise, built-in lighting, with cover opening and parking function,

which improves the protection level.

4.1.24 ﹣ a 6-hole reel is

provided for the position of the wire collecting tube of the winch, which can

be moved back and forth to adapt to different wire stranding angles, and

other users are equipped by themselves

|

Ningbo Capstian Technology Co.,Ltd.

Ningbo Capstian Technology Co.,Ltd.